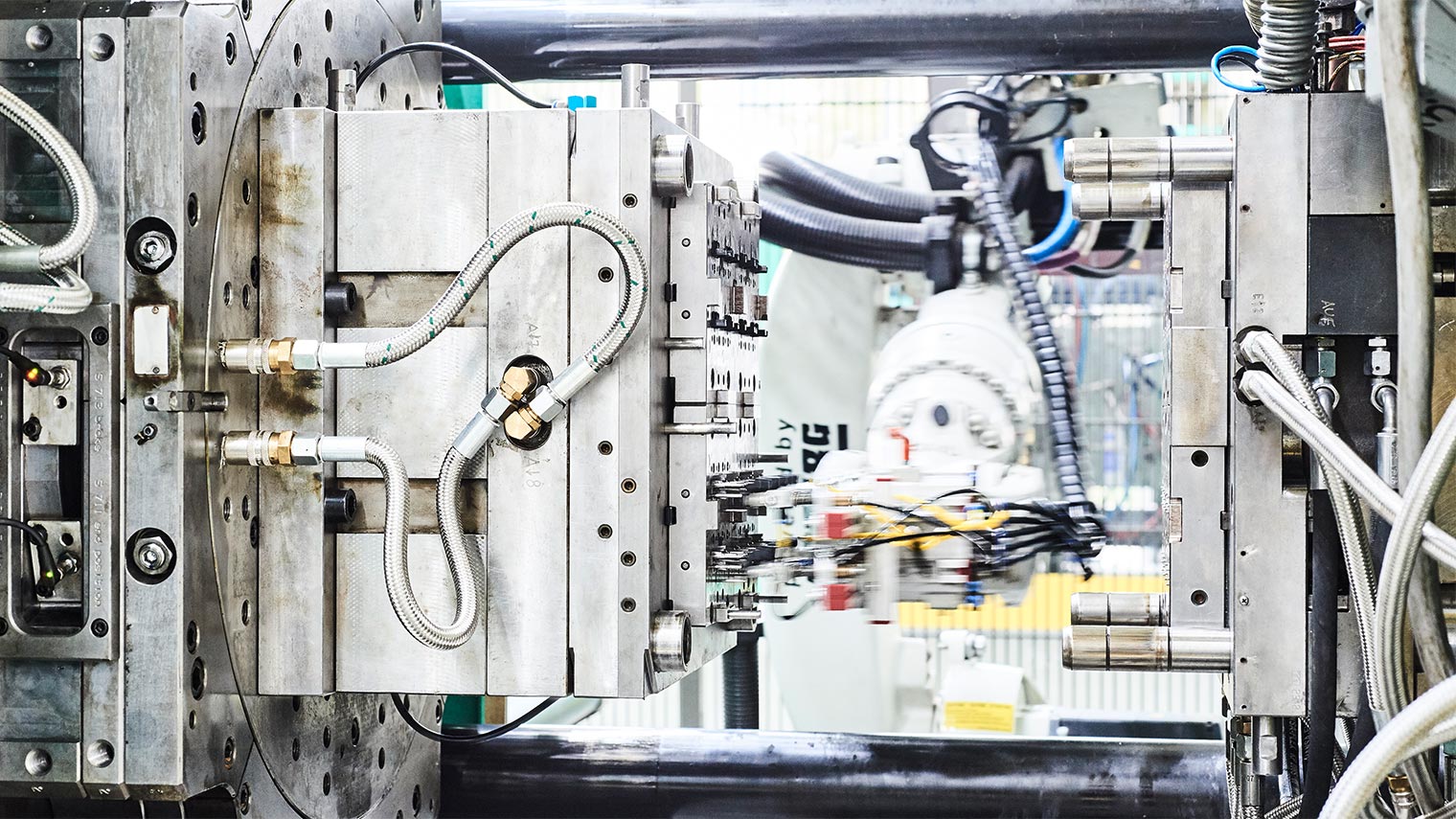

Plastic injection

moulding

with that decisive

Innovative project management

With plastic injection moulding, no two jobs are ever the same. This is because the specifications for each part, product or project are always different. Whether the production process is based on the overmoulding of inserts (stamped, turned or electronic components) or multicomponent moulding, our drive for quality remains the same. In each case, automated processes ensure a precise synthesis of different materials. On behalf of our customers, we develop innovative injection-moulding processes, using the full range of thermoplastics and also high-temperature plastics in, for example, dual-component injection moulding. We also conduct research and joint projects with the Kunststoff-Institut Lüdenscheid, which has an outstation in Villingen-Schwenningen, close to our company location. This enables us to offer our customers test sequences in line with automotive standards.

Development of plastic parts

- Development of innovative injection-moulding processes

- Gear technology

- Insert applications

- Mechatronic assemblies

Plastics

- Full range of thermoplastics, reinforced and non-reinforced

- PA, POM, PBT, PP, ABS and many others

- High-temperature plastics: PEEK, PPSU, PEI, LCP and PPS

Precision injection moulding

- Customised gear components

Multicomponent injection moulding

- Transfer method

- Index method

- Rotation method

Hybrid injection moulding

- Metal parts

- Electronics